Manual Handling Weight Limits: What are the Safe Lifting Guidelines and Techniques?

Manual handling is one of the primary causes of workplace accidents and ill-health in the UK. In 2022/23, there were 132,000 new cases of work-related musculoskeletal disorders (which is one of the most common consequences of poor manual handling practices) and 473,000 total cases including long-standing ones. It accounted for 6.6 million working days lost and was the second highest cause of work-related ill-health, accounting for 27% of cases.

As these statistics reveal, the consequences of poor manual handling are all too common and can significantly affect people’s health. It’s therefore important that you understand safe manual handling weight limits and handling techniques for preventing harm to the body. You should be aware of what factors affect a person’s ability to perform tasks safely.

Need a Manual Handling Course?

Our Manual Handling Training course helps to ensure that you are sufficiently trained in the principles and practices of safe manual handling. You can also find a range of our Health & Safety courses here.

Health and safety law in the UK requires businesses to protect the wellbeing of their employees. Following good manual handling techniques and adhering to weight limits will therefore also ensure your business complies with safe manual handling procedures, as set out by the relevant UK legislation and guidance documents.

This article will provide a thorough overview of the manual handling weight limits and guidelines that are set out in the law and advised by the Health and Safety Executive (HSE).

What are the Manual Handling Weight Limits for Lifting at Work?

There are no specific limits for manual handling and lifting at work, because it depends on a variety of factors, such as the type of task and the individual capabilities of the worker.

Under the Manual Handling Operations Regulations (MHOR) 1992, employers must take appropriate steps to reduce the risk of injury posed to employees by manual handling operations to the lowest level reasonably practicable. The specific weight limits and manual handling procedures required to achieve this will vary depending on each type of manual handling activity.

According to the hierarchy of measures set out by the MHOR, avoiding manual handling operations should always be considered first, e.g. by using automation like production lines. If this isn’t possible, the duty holder must assess the risks posed by manual handling activities in the workplace and determine what is needed to control them. This involves carry out a risk assessment of the manual handling activities. They must then put the necessary safety measures in place to reduce the risks to people’s health and safety.

There are 4 key factors that duty holders need to consider during the risk assessment for manual handling:

- The task. For example, how long it will take, how frequently it’s carried out, whether it is repetitive, whether it provides sufficient rest or recovery, and if it involves twisting, stooping, or reaching upwards. These can all affect how strenuous the work is.

- The individual. Everyone’s physical capabilities and limitations differ due to a number of factors, such as the person’s age or their physical dimensions. Some people may be particularly at risk, such as new or expectant mothers, people with disabilities, and those returning to work from a recent injury. No two people are alike, so employers must ensure they’re protecting everyone from health and safety risks equally by adjusting the work and safety precautions according to their abilities.

- The load. If it is oversized or bulky, difficult to grasp, and has a shifting centre of gravity (such as if it contains liquid), then it can be difficult for the person to get a solid grip and hold the load steady. This may result in more strain being placed on the body.

- The environment. For example, if there isn’t enough space in the area for the person handling the load to move comfortably, if the floor is bumpy or has variations in levels, or if the person can’t see properly, then the task will be more difficult and therefore more strenuous to carry out. Psychological responses to the work and workplace conditions can also put people at greater risk, such as high workloads, tight deadlines, and lack of control over the work and working methods.

These four factors are known as TILE, or sometimes LITE. They are vital to keep in mind when identifying safe lifting and weight limits for certain manual handling activities. In light of these factors and various other guidance, the MHOR and various HSE manual handling guidance documents set out some suggested manual handling weight limits for lifting, carrying, pushing, pulling, and team activities.

As there is no one size fits all approach, this information needs to be considered in the context of the specific manual handling activities in your workplace. However, the guidance documents are useful tools for helping the person in charge of setting the necessary manual handling limits.

Safe Lifting Weights: the HSE’s Lifting and Lowering Risk Filter

Although the MHOR do not set specific weight limits, the HSE outlines some guidelines for lifting and lowering. They should not be referred to as ‘safe limits’ as this depends on all the factors involved as discussed earlier, but the HSE states they use “broad assumptions or generalisations where, if met, the risk of injury is considered to be low.” Working outside of these suggested ranges is likely to increase the risk of injury.

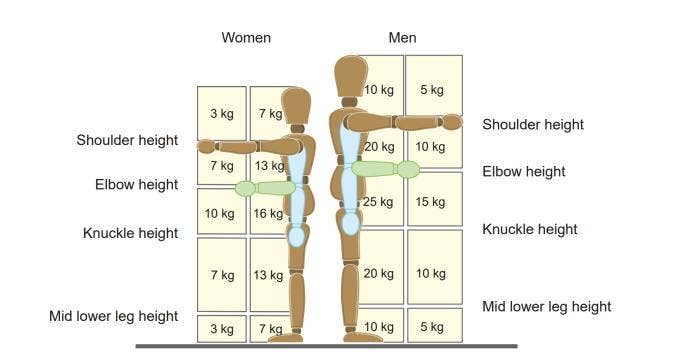

The HSE’s lifting and lowering risk filter outlines general safe lifting capacities for men and women, based on data from the general population:

As this shows, a 25 kg load being manually handled is considered to be a safe upper limit for the average man and 16 kg for the average woman.

It’s important to note, however, that this is only if the person carrying the load can keep it at knuckle height and close to their body. If a load passes between the zones, e.g. if you lift a box from knuckle height to a shelf at shoulder height, it would no longer be safe to handle a 25 kg load. If you anticipate the load will pass between zones during the task, then the lower weight must be adhered to.

Whether the person’s arms need to extend must be factored in too. For example, if the manual handling activity involves carrying a 16 kg load at elbow height, the advised limit for extended arms in this zone is 10 kg, so the weight of the load must be reduced in order to be safe.

Furthermore, it’s vital to understand that these risk filters only apply to manual handling activities where the load:

- Is easily grasped with both hands.

- Is in reasonable working conditions.

- Can be held with the worker in a stable body position and using safe lifting and handling techniques.

- Is able to be held against the body.

- Is carried no further than about 10 metres without rest.

- Does not prevent the person from walking normally.

- Does not obstruct the carrier’s view.

- Does not require the carrier’s hands to be below knuckle height or much above elbow height.

- Can be securely loaded onto the shoulder without needing to be lifted first (e.g. by sliding it onto your shoulder from a shoulder-height shelf.) In this situation, the filter values can be applied up to 20 metres.

Certain factors will require manual handling activities to undergo a more thorough assessment, and may need different weight limits and handling practices.

For example, if the weights exceed those in the above risk filter, if the handling involves twisting, if the handling is carried out more frequently than one lift every 2 minutes, if it involves a team, if weights vary significantly, if the load is difficult to grasp, and if the person is at an increased risk (e.g. those with disabilities or a recent injury).

To identify these higher-risk manual handling activities, the HSE has created the Manual Handling Assessment Charts (MAC) for duty holders to use. It will help them understand what factors may need modifying to control high risk manual handling tasks.

Safe Lifting Weights and Techniques: the HSE’s Manual Handling Assessment Charts

The HSE Manual Handling Assessment Charts (the MAC tool) helps duty holders assess the most common risk factors in lifting and lowering, carrying, and team handling operations. It uses a variety of illustrations and infographics to help demonstrate how various factors increase the level of risk, and how each risk range will require careful consideration of how to protect people’s wellbeing.

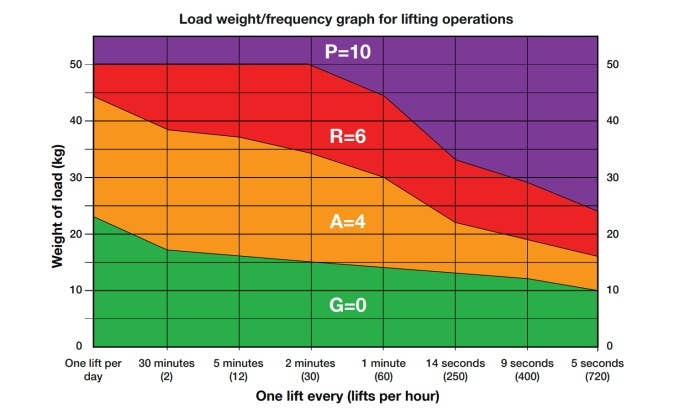

For example, the first area covered in this guide is assessing the load weight and frequency involved in lifting. It shows how the level of risk increases where the rate of the lift and its weight increase.

When tasks enter a new colour band, this means the risk has increased and further control measures to ensure safety are likely to be required compared to lower bands.

The manual handling risk areas covered by the MAC tool are:

Lifting operations:

- Load weight/frequency.

- Hand distance from the lower back.

- Vertical lift zones.

- Torso twisting and sideways bending.

- Postural constraints.

- Grip on the load.

- Floor surface.

- Environmental factors.

Carrying operations:

- Load weight/frequency.

- Hand distance from the lower back.

- Asymmetrical torso or load.

- Postural constraints.

- Grip on the load.

- Floor surface.

- Carry distance.

- Obstacles on route.

- Environmental factors.

Team handling operations:

- Load weight.

- Hand distance from the lower back.

- Vertical lift zones.

- Torso twisting and sideways bending.

- Postural constraints.

- Grip on the load.

- Floor surface.

- Carry distance.

- Obstacles on route.

- Communication, coordination, and control.

- Environmental factors.

If any of these apply to your work, it will be important for your employer to consider the guidance in the MAC tool and the risk zones set out for each area.

For example:

- Lifting a load every five minutes (12 per hour) that is below 15 kg is considered safe, whereas lifting a load every minute (60 per hour) that is above 45 kg enters the purple zone, which means it is an unacceptable level of risk and operations may present a serious risk of injury, requiring immediate improvements.

- Carrying one load every 30 minutes (two per hour) that is below 20 kg is considered safe, whereas carrying a load every minute (60 per hour) that is above 20 kg enters the amber zone, which means it needs to be monitored closely for risks to the carrier’s health and safety.

- Two people carrying a load weighing 65 kg – 85 kg is considered in the red risk zone. This means the task may expose the workers to a risk of injury and prompt action will be needed.

To view the full guidance document, which will help you identify what factors make certain manual handling tasks higher risk, visit the following HSE link: Manual Handling Assessment Charts (the MAC tool).

Safe Manual Handling Procedures: HSE Guidance for Pushing, Pulling, and Repetitive Tasks of Upper Limbs

The HSE has also published guidance documents that function similarly to the Manual Handling Assessment Charts, but are designed for pushing and pulling activities (the RAPP tool) as well as manual handling activities that are identified as repetitive tasks of upper limbs (the ART tool). Like the MAC tool, these will help duty holders identify what factors can affect the safety of pushing and pulling, and repetitive tasks that require using the upper limbs.

For example:

- If the equipment used to help move a load is small with one or two wheels (e.g. a wheelbarrow) and, combined with the weight of the load, weighs between 100 kg to 200 kg, this enters the high-risk zone and exposes the worker to a risk of injury, meaning prompt action is needed.

- If the person’s body has to be severely bent, twisted, or inclined during a pushing or pulling operation, this enters the high-risk zone.

- If the work is not too repetitive, e.g. 10 times per minute or less, the risk is within an acceptable zone. However, if it is highly repetitious, e.g. if a similar motion pattern of the arm and hand is repeated more than 20 times per minute, this enters the high-risk zone.

- If a light amount of force has to be exerted with the hand part of the time (15% to 30% of the time) then the risk is within an acceptable zone. However, if a strong level of force has to be exerted with the hand almost all of the time during the operation (80% or more of the time), this enters the high-risk zone and changes are required.

To view the full guidance documents, which will help you identify what factors make certain pushing, pulling, and repetitive tasks of the upper limbs higher risk, visit the following HSE links: Risk Assessment of Pushing and Pulling (RAPP) Tool and Assessment of repetitive tasks of the upper limbs (the ART tool).

Safe Lifting and Handling Techniques

It’s vital that those carrying out manual handling operations understand how to adopt safe handling techniques. Whether or not you’re able to do so can greatly affect the safety of the task and what weight limits are suitable, as outlined in the HSE guidance documents discussed above.

To carry out manual handling procedures safely, you should:

- Position yourself next to the load with feet flat on the floor, hip-width apart, and with one leg slightly forward to maintain balance.

- Bend to pick up and lift the load using your back, hips, and knees, keeping your back straight as you do so.

- Get a good grip on the load and hold it as close as possible to your body (with the heaviest side against your body).

- Keep your head up when handling and carrying the load. Ensure you are able to look over the load so you can watch where you’re going.

- Move slowly and carefully to keep control.

- Avoid twisting your back or leaning sideways. Keep shoulders level and facing the same direction as your hips.

- Avoid lifting the load above your shoulders or letting it drop below your waist.

- Put down and adjust the load along your route if necessary and possible.

- Aim to push rather than pull where possible.

- Avoid lifting from floor level or above shoulder height where possible.

- Ensure the work environment is safe for you to carry out the task in, e.g. has good lighting conditions, a clear path, and an even, non-slip surface.

One final thing to remember is that, even if you don’t feel strain after one or two incidents of overextending, manual handling activities can very easily cause harm to your body in the long run. By the time you recognise a task is causing problems, you may have already suffered a long-term injury.

This is why it’s so important for duty holders to assess the risks and put in place the right safe manual handling procedures for their business’s work activities. Likewise, it’s important for employees to follow these control measures and adopt good practices and techniques, as well as listen to the limitations of their body. They should communicate with their manager or supervisor, or a representative, if they have concerns about their manual handling activities, so their employer can take steps to reduce the risks to their health and safety.

Further Resources:

- Manual Handling Quiz

- What are the Consequences of Poor Manual Handling?

- Manual Handling Techniques and Tips

- Manual Handling Training: What are the Regulations?

- Warehouse Safety Quiz

- Team Manual Handling Tips

- 40 Warehouse Safety Tips

- Online Manual Handling Training Course