Understanding the Marking System for Abrasive Wheels

A grinding wheel, also known as an abrasive wheel, is a wheel made of abrasive particles bound together by various substances, such as rubber, shellac or silicate. They are used by a variety of industries but, if not used safely, have the potential to cause serious injury.

All abrasive wheels are prone to breakage so it’s essential that you always follow best working practices whenever they are in operation. One of the first control measures to adhere to is ensuring that you understand the marking system for grinding wheels.

Need a Training Course?

Our Abrasive Wheels Training will provide you with an introduction to working safely with abrasive wheels so that you can understand the risks and know which control measures are needed to prevent injury and ill-health.

Abrasive Wheel Markings

All abrasive wheels are marked with:

- Type.

- Size.

- Specification.

- Maximum operating speed.

- Restrictions for use.

- Other, non-safety related information.

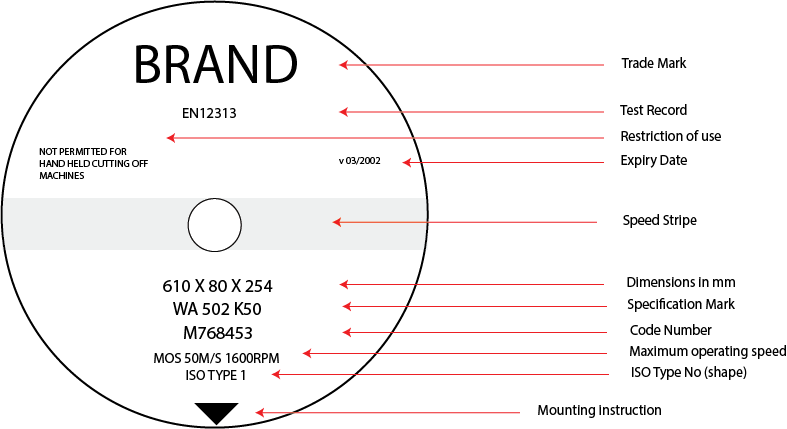

They must conform to the British Standard (BS EN 12413 and BS ISO 525) system for marking. Take a look at the example below which shows each of the essential markings.

The type of the wheel is marked as an ISO number and signifies the wheel’s shape. For example, ISO Type 52 is a spindle-mounted wheel.

The size of the grinding wheel is marked as dimensions in mm. For example, 230 x 3 x 22.2mm. This represents the wheel’s diameter x thickness x hole size.

The specification of the grinding wheel is marked as a series of letters and numbers. For example, WA 60 K 7 V. This represents the type of abrasive material, the grit size, the grade, the structure and the bond type. A general guide to specification marking can be seen in the table here:

|

Example |

Marking |

Marking Codes |

|

WA |

Abrasive Material |

A – regular aluminium oxide WA – white aluminium oxide 19A – mixture of A and WA SD – synthetic diamond ASD – synthetic diamond, metal coating FA – semi-friable aluminium oxide PA – pink aluminium oxide SA (HA) – single crystal aluminium oxide 23A – mixture of A and SA AZ – zirconium oxide C – black silicon carbide GC – green silicon carbide RC – mixture of C and GC |

|

60 |

Grit Size |

(Coarse) 10, 12, 14, 16, 20 etc. to 600, 800, 100, 1200 (Fine) |

|

K |

Grade |

(Soft) A, B, C, D, E etc. through to V, W, X, Y, X (Hard) |

|

7 |

Structure |

(Dense) 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14 (Open) |

|

V |

Bond Type |

V – vitrified B – resinoid R – rubber O – MgO E – epoxy M – metal EP – electroplated |

The range of material markings, grit sizes, grades, structures and bonds depends on the product and the manufacturer, but the table above gives a general outline of common markings seen on abrasive wheels.

The maximum operating speed is marked on every large grinding wheel (above 80mm in diameter) in two ways:

- The peripheral surface speed, given in metres per second. For example, 80m/s.

- The rotational speed, given in revolutions per minute. For example, 8500rpm.

For smaller grinding wheels (below 80mm in diameter), the maximum operating speed is provided on a separate notice which must be stored alongside the wheel.

For high speeds, colour-coded stripes are also marked across the centre of the wheel. The colours are:

- 50m/s – Blue

- 60m/s – Yellow

- 80m/s – Red

- 100m/s – Green

- 125m/s – Blue/Yellow

The restrictions for use are marked on the grinding wheel using a code and, in some cases, a corresponding graphic. The markings used to show restrictions are as follows:

| Restriction Code | Meaning |

| RE1 | Not permitted for hand-held and manually guided grinding |

| RE2 | Not permitted for hand-held cutting-off machines |

| RE3 | Not suitable for wet grinding |

| RE4 | Only permitted for totally enclosed working area |

| RE6 | Not permitted for face grinding |

Non-safety related markings found on grinding wheels are:

- The manufacturer’s trademark/name.

- The test record number, indicating it meets the standards for safety.

- The expiry date if it’s an organic bonded wheel (this will be 3 years from the date of manufacture).

- A traceable code number, indicating the source and manufacturing details of the wheel.

- A mounting arrow, indicating the heaviest point of the wheel. The arrow should point downwards when the wheel is mounted.

If you work with abrasive wheels then having an understanding of their markings is essential, but this isn’t where your knowledge should end. All operators should have a strong awareness of the hazards associated with grinding wheels, as well as how to correctly store and handle them, inspect them for damage and follow appropriate control measures.

Further Resources:

- 15 Workshop Hazards and How to Avoid Them

- Classification of Grinding Wheels: Which Do I Need?

- What are the Hazards of Grinding?

- Welding Hazards in the Workplace: Safety Tips & Precautions

- Grinding Safety Precautions and Control Measures

- Abrasive Wheels Training