Cellar Management Course

Quantity: 1

Duration 2 Hours

100% online training

Start when you like

Learn on any device (desktop, mobile or tablet)

Instant assessment and result

1 learner per course

Train teams of all sizes

Bulk discounts starting at 10% off 10 courses

Pay by invoice with 30 day payment terms available (5+ courses)

Includes a 10% discount for 10+ courses

This Cellar Management course will ensure that all employees working in any establishment with a bar have the appropriate knowledge needed to properly store, prepare and pour cask ales and keg beers.

Untrained bar staff can be responsible for up to £16,000 worth of wasted stock every year on a classic six-tap account, as well as lost reputation if flat, sub-par pints are poured. For this reason, Cellar Management training is recommended to ensure that your establishment succeeds.

100% online training

Access anywhere

Same day digital certificate

Printed certificate posted next working day

Full audio voiceover

Assessment retakes at no extra cost

Developed with consultation from Cask Marque

Accredited by CPD and endorsed by the Institute of Hospitality

Bulk discount for orders of 10+ courses

Save on our courses when you buy more training upfront. Lock in a better price now and access the training whenever you need to. You can mix and match any of our courses too and get the discount off your whole order.

10+ courses = 10% off

50+ courses = 20% off

100+ courses = 30% off

500+ courses = 40% off

By the end of this course, you will:

Accredited by CPD

All of our courses are accredited by the CPD Certification Service as conforming to universally accepted Continuing Professional Development (CPD) guidelines.

Endorsed by the Institute of Hospitality

Additionally, this course is endorsed by the Institute of Hospitality as providing independently-evaluated, quality content that teaches good practice standards.

Developed in collaboration with industry experts and Cask Marque

This Cellar Management training course has been created with consultation from Cask Marque, the organisation who aim to ensure high standards of beer quality across the UK. You can learn more and apply to join the scheme on the Cask Marque website.

Recommended renewal:

3 years

What does this mean? This certificate does not have an expiry date, however, based on industry best practice guidelines there is a recommended renewal period.

Our in-house Learning Designers develop all of our courses to give you and your learners the most engaging training possible.

Benefits of good cellar management, what is a 'perfect pint', the types and styles of beer available, employer and employee responsibilities in the workplace, risk assessments, accident reporting and accident record keeping.

Cellar deliveries, cellar drops, drop and door safety, awareness of hazards, how to receive deliveries and store your beer, preparing cask for service and the storage of kegs.

Gas management and safety, personal protective equipment for the safe handling of gas cylinders, what should be done in the event of a gas leak, fire and gas, various types of keg couplers and lifting procedures.

Cellar hygiene, cask line cleaning, keg line cleaning, COSHH regulations.

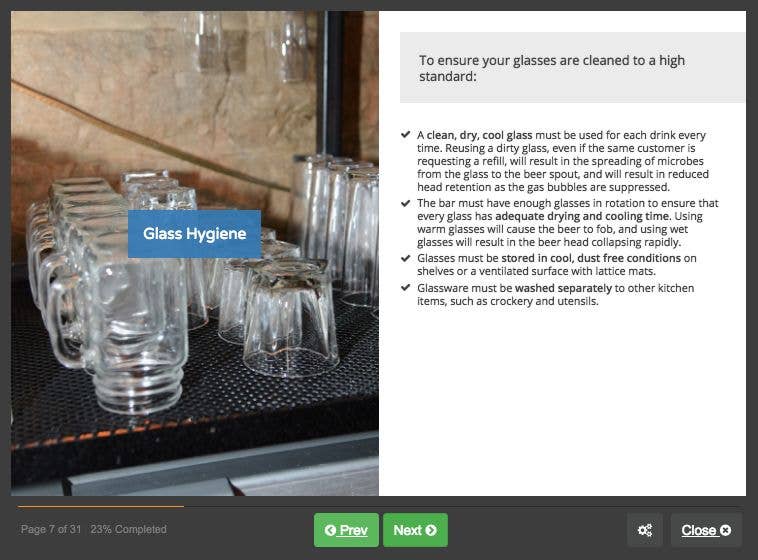

Bar hygiene, glass hygiene, personal hygiene, health and safety, wastage control and pulling the perfect pint.

Troubleshooting for no beer at the dispense, off-tasting beer, flat beer and hazy beer.

The online assessment is taken on completion of the training material. You will be asked 15 multiple choice questions with a pass mark of 80%. The answers are marked automatically so you will instantly know whether you have passed. If you don't pass don't worry! You can take the test as many times as you need with no extra charge.

This Cellar Management course is ideal for owners, managers, supervisors or anyone who is responsible for line cleaning, barrel changing, cellar health & safety or the profitability of the business on a daily basis.

This training covers best practices and topics such as: