3 Case Studies of Working in Confined Spaces

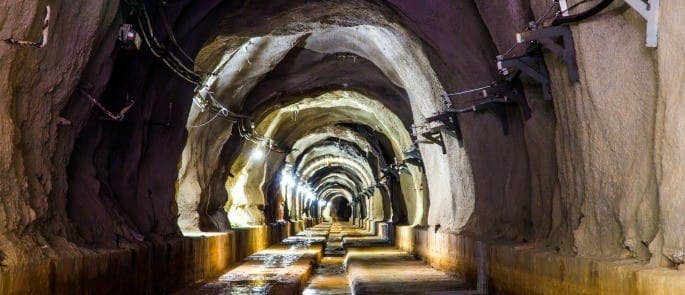

When you hear the phrase ‘working in confined spaces’ you probably think of tight, enclosed areas that trigger the claustrophobia you didn’t even know you had. However, it’s not just coffin-like environments that are defined as confined.

In this article we highlight some common examples of confined spaces, and give three real life case studies of related workplace incidents.

What is a Confined Working Environment?

Spaces that are enclosed, or largely enclosed, and threaten the health and safety of workers due to the risks of fire, explosion, asphyxiation, drowning, or loss of consciousness are by definition confined spaces. Here we cover some real examples of confined spaces.

The obvious examples include:

- Storage tanks.

- Silos.

- Reaction vessels.

- Enclosed drains.

- Manholes.

- Ship holds.

- Sewers.

The less obvious examples include:

- Open-topped chambers.

- Chambers in furnaces.

- Ductwork.

- Unventilated/poorly ventilated rooms.

- Cargo holds and freight containers.

- Cold storage rooms.

- Excavations and trenches.

There will be numerous others no doubt; it’s difficult to compile a comprehensive list. The dangers that make an environment become classed as confined – e.g. a lack of oxygen or poisonous gases – can affect even those environments not normally classified as such when typical conditions change.

The sad truth is that over 60% of confined space fatalities are those attempting to rescue others.

Of the three working in confined spaces case studies we will look at, two of them involved the fatalities of rescuers. This just goes to show that an awareness of the risks posed by confined spaces and the importance of safety and rescue procedures need more attention from not just those working in confined spaces, but from everyone.

Case study 1: Asphyxiation in underground drainage system

In 2011, two brothers, aged 16 and 22, died due to the hazardous environment in an organic waste recycling facility. While they were flushing out the drainage system with a high-pressure hose, the younger brother was asphyxiated by hydrogen sulphide, which caused him to fall to the bottom of a 10-foot shaft. His older brother attempted to rescue his brother but sadly met the same fate and died 2 days later in hospital.

During the investigation, high levels of hydrogen sulphide were confirmed to be present. The organic waste in the facility no doubt caused the build-up of this extremely hazardous gas; the bacterial breakdown of organic materials and human/animal waste emits hydrogen sulphide.

Case study 2: Electrician rendered unconscious in a waste gas tower

In 1999, an electrician was knocked unconscious from the fumes within a waste gas tower. Dangerous amounts of carbon monoxide, dihydrogen sulphide, hydrogen cyanide, and other toxic gases were present – you don’t need to be an expert in chemistry to know that this could have very easily killed him. Luckily, a student was accompanying him that day.

They were both inside the skirt underneath the gas tower, on their hands and knees working on a motor. The electrician suddenly became motionless and unresponsive – knocked unconscious by the gases. Although the student felt ill himself due to the fumes, he managed to pull the electrician to safety. Both were very fortunate to survive this extremely hazardous atmosphere.

Case study 3: Oxygen depletion in a barge’s chamber

Four men were involved in this incident. A fault was identified in a crane’s hydraulics, so two men entered the confined chamber to inspect the pipework, but they were unaware that the rusting of the boat’s metal hull had consumed most of the oxygen in the chamber.

Within a minute, the first man had passed out. The second was disoriented but managed to escape and raise the alarm. In an attempt to rescue the man knocked unconscious, two other workers then entered the area but were both overcome and asphyxiated due to the lack of oxygen. The rescuers died while the first two men survived.

How could these incidents have been prevented?

In the first case study, the employer did not identify that the shaft and drainage system were permit-required confined spaces, and therefore had insufficient procedures in place. There were no preventative measures – such as breathing apparatus to shield them from the dangerous gases, or rescue procedures – in place to ensure the safe rescue of those in danger. Had legitimate rescue procedures been in place, the 22 year old who sadly died attempting to rescue his brother, could have survived.

In the second case study, it was discovered that no risk assessment had been carried out prior to the job, there was no rescue plan in place, and the isolation procedure failed because a vent was closed – which if open would have prevented gas from entering the tower. Failure to assess the dangers and ensure that there was a contingency plan led to the lives of the electrician and the student being put in danger.

In the third case study, the companies that employed the victims confessed that they had not:

- surveyed the confined areas.

- provided employees with sufficient training.

- established a safe system of work.

If an awareness of the risks posed by working in a confined space on a boat – which was prone to oxygen being consumed by rust – had been provided by the responsible employers, the employees would have been able to avoid the area or follow safety procedures, and may not have lost their lives.

What should be done?

In confined spaces such as described, employers should be sure to carry out the following safety procedures:

- Air should be tested by a qualified person using air monitoring equipment that is correctly calibrated. The atmosphere in a confined space can be tested from the outside with a long probe so that physical entry is not necessary. The oxygen levels should be checked and hazardous gases identified.

- Natural ventilation or mechanical ventilation should be put in place where possible to ensure that workers can breathe easily, healthily, and safely. Fresh air should be drawn from a point where it is not contaminated.

- Respiratory protective equipment should be provided to those who work in the confined space if ventilation cannot completely remove dangerous gas. The filters must be suitable for their purpose, and equipment must be fitted correctly.

- Proper rescue and retrieval procedures should be in place – e.g. the use of lifelines and lifting equipment or additional sets of breathing apparatus. People operating within a confined space should also have a means of communicating to people outside the confined space in an emergency.

- A hazard communication program or training must be provided to employees who may work in confined spaces in their job roles so that they are aware of the dangers that could arise, that they know how to identify them, and understand what to do in an emergency.

These are just some examples of the safety procedures and control measures you should implement.

The dangers posed by confined spaces are not confined to the examples listed here, or those seen in the case studies. But as is apparent, they pose a very real threat, and every precautionary measure must be taken. It is literally the difference between life and death, and in many cases, as above, it is fortune that ensures the survivors walked away from the confined spaces mostly harm-free.

Don’t leave it to fortune; educate yourself on the risks of confined spaces and the safe systems of work to protect yourself, your team and your workforce from harm in hazardous confined spaces environments.

Need a Course?

Our Working in Confined Spaces Training has been designed as an introduction to the topic so learners can understand more about safe work practices, suitable control measures and what the law says in regards to staying safe at work.

Further Resources:

- What are the Requirements for Working in Confined Spaces?

- What are the Emergency & Rescue Procedures for Working in Confined Spaces?

- Working in Confined Spaces Hazards and Control Measures

- Working in Confined Spaces Course