Working in Confined Spaces Hazards and Control Measures

Confined spaces, by their very nature, can present many hazards to workers and those in the vicinity, including fires, explosions, drowning, and asphyxiation caused by gases, fumes, vapours, free-flowing materials, or a lack of oxygen. A significant majority of these incidents occur as a result of inadequate planning, controls and training for those planning and undertaking the work.

This article will discuss the main hazards associated with working in confined spaces, as well as key elements of general control measures that may be used to control the hazards associated with your work activities.

What are the Hazards of Working in Confined Spaces?

A space must have two key defining features present in order to be considered a ‘confined space’.These are that the space must be substantially (though not always entirely) enclosed and that one or more of the specified risks must be present or reasonably foreseeable.

What are the Specified Risks?

As mentioned above, for a space to be ‘confined’ it must have one or more of the specified risks present. There are six specified risks defined by the the Confined Spaces Regulations 1997 and its Approved Code of Practice (ACoP). These are a risk of:

- Serious injury arising from fire and/or explosion caused by flammable substances (liquid, solid or gas) or by enrichment of the atmosphere by oxygen leading to enhanced risk of fire.

- Loss of consciousness caused by an increase in body temperature due to excessive heat.

- Loss of consciousness or asphyxiation caused by gas, fume or vapour.

- Loss of consciousness caused by oxygen deficiency occurring where the level of oxygen in the air is reduced to a dangerous level.

- Drowning caused by liquids entering the confined space.

- Asphyxiation, or becoming trapped and unable to reach a respirable environment, by free-flowing solids such as grain, sand or other free-flowing materials.

Examples of Confined Spaces

Some examples of confined spaces include:

- Manholes, shafts and tunnels.

- Sumps and inspection pits.

- Enclosed rooms, such as plant rooms.

- Storage of wood pellets or other oxidising agents in hoppers or bins.

- Silos and storage vessels.

- Interiors of vehicles, such as closed vans.

- Cold storage rooms or other food preservation rooms.

This list is not exhaustive. For a space to be defined as a ‘confined space’ it must have both of the defining features outlined above. You should note that some spaces can become ‘confined’ if the conditions change. For example, if the degree of enclosure is changed or there is another change that introduces the presence or foreseeable risk of one of the ‘specified risks’. This also applies in reverse; so a space may no longer be considered ‘confined’ if the source of any present or foreseeable ‘specified risks’ is removed or the degree of enclosure is lessened.

This article provides a brief overview of confined spaces – if you require more training on Working in Confined Spaces, take a look at our Working in Confined Spaces Online Training Course.

Other hazards associated with confined spaces

Further to the specified risks outlined above, it’s vital to understand that there are many other hazards that can also pose risks to those working in confined spaces. These include, but are not limited to:

- Restricted access and movement as a result of narrow openings or access points. This can result in restricted or awkward working positions, trapping, and collisions with the structure or protruding objects.

- Exposure to electricity. For example, from the use of electrical equipment that is not suitable for use in confined spaces, or the specific working conditions or activities being undertaken.

- Slips, trips and falls. The conditions in a confined space can increase the risk of slips, trips and falls, such as fragile or slippery surfaces, and poor lighting.

Risk Assessments

Confined spaces pose many hazards to those working in them and anyone in the vicinity. Under the Management of Health and Safety at Work (MHSW) Regulations 1999, the Confined Spaces Regulations 1997 and its ACoP, employers have a legal duty to ensure a risk assessment is carried out to assess, control and monitor the risks associated with their work activities so that their employees remain safe from harm.

The rest of this article will explore the key elements of general control measures that may be used to control the risks associated with confined spaces.

This article does not contain an exhaustive list of control measures. The control measures used for your work activities must be tailored to, and suitable for, the specific hazards posed by your work activities and considered in line with the hierarchy of control.

Note that: for employers who employ five or more people, it is a legal requirement that their risk assessment is recorded. The following handy downloadable template can be used to record your risk assessment. The template is an easy to use template that has two columns; one for current controls and one for what further controls may be required:

Control Measures for Working in Confined Spaces

The Confined Spaces Regulations and its ACoP place a legal duty on dutyholders (employers, the self-employed, and those in control of premises) to avoid the need to enter or work in confined spaces as their first duty.

Where it is reasonably practicable to conduct the work activity from outside of a confined space, the dutyholder has a legal responsibility to prevent entry to the confined space by themselves or others. On every occasion, the dutyholder must consider if it is possible to avoid entry to and work in the confined space.

Methods of avoiding entry to confined spaces include:

- Using remotely operated devices.

- Installing portholes, sight glasses or inspection windows.

- Replacing storage containers instead of entering to repair them.

- Using remote cameras.

Safe Systems of Work

Where it is not reasonably practicable to avoid entry into a confined space, employers must ensure a safe system of work is in place. A safe system of work forms part of the risk assessment process for a confined space, it must not replace it. The key elements of a safe system of work are:

- Safe Place of Work – The entries to all places of work should be sufficient and safe for entry and located in the safest possible place. Lighting, access and ventilation should be adequate.

- Safe Work Equipment – The safe system of work should only permit the use of the safest work equipment possible. For example, low voltage electric generators rather than petrol or diesel generators.

- Safe Substances for Use at Work – The safe system of work should only allow the safest substances possible. This may mean substituting dangerous, flammable or toxic substances, such as chemicals or gases, for safer alternatives.

- Safe Management, Supervision and Monitoring – Managers, supervisors, those who plan the work, and other dutyholders should be competent in their duties, including an understanding of the hazards and risk of confined spaces and how to safely supervise and monitor activities.

- Safe Workers – Employees and others at work in the confined space must be fully trained in the safe system of work, including any work equipment and use of substances, and in rescue arrangements.

Atmospheric Testing and Monitoring

If there is any foreseeable risk of reduced oxygen levels, or the presence of natural or man-made hazardous substances in the confined space, testing of the atmosphere must be undertaken before and during entry. Where reasonably practicable, this testing must be undertaken from outside of the confined space. If there is a risk that the atmosphere may deteriorate as the work activities are carried out, atmospheric monitoring may be required throughout the full duration of the work activity to ensure the air in the confined space remains safe to breathe.

Isolation

Confined spaces must be properly isolated to prevent entry of hazardous or dangerous substances, including gases, vapours, liquids and solids, and to secure mechanical and electrical equipment. Methods of isolation include:

- Isolating the confined space by ensuring valves are properly turned off and locked off.

- Disconnecting the confined space completely from other plant, such as by blanking off a pipe using an end cap.

- Ensuring that any walls or partitions used to isolate an area are checked and reinforced, where necessary.

Cleaning and Removal of Residues

Many confined space work activities are undertaken to clean or remove residues. These activities may be undertaken to keep a confined space clean and free from contamination, or to remove residues that may be hazardous or harmful to health prior to planned work in a confined space. These residues may be natural or man-made. Precautions for work where residues may be present include purging the confined space using an inert gas, using mechanical ventilation, and using protected-low voltage equipment.

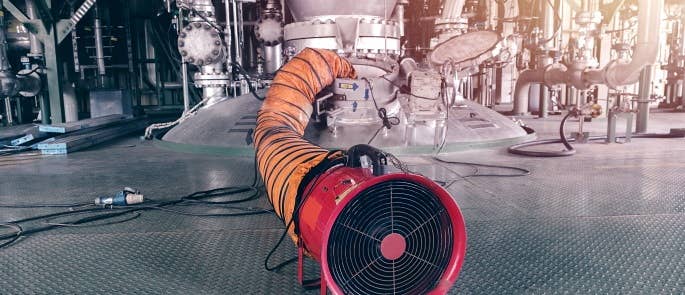

Confined Space Ventilation

Ensuring adequate ventilation is essential prior to entry into a confined space. Considering ventilation of a confined space must take into account:

- The confined space layout.

- Natural ventilation and air circulation within the space.

- The size and positioning of openings.

- Possible pollutants in the space.

- The complexity of the space, such as if there are pockets that may allow pollutants to sit in the space and concentrate.

When using mechanical ventilation, care must be taken to ensure that there is a sufficient supply of breathable air – air must not be drawn from a place where it can become contaminated, such as next to a diesel generator exhaust. In addition, air extracted from the confined space must not be able to re-enter the space.

Fire Prevention

In order for a fire to start, there must be a source of ignition, fuel and oxygen present. To prevent a fire, these must be removed. Where the presence of a source of ignition, fuel or oxygen is unavoidable, appropriate controls must be enforced to prevent a fire. These controls include:

- Properly removing residues prior to work commencing.

- Minimising the use of combustible materials.

- Never leaving combustible materials in a confined space. Where this is unavoidable, they should be stored in fire resistant containers.

- Never using oxygen to ‘sweeten’ the air, as this can result in spontaneous combustion of substances.

Permit-to-work systems

A permit-to-work system is a written procedure to ensure that specific entry requirements and work activities in a confined space are followed, which is usually required where there is a reasonably foreseeable risk of serious injury occurring from entry or work in a confined space.

Please note that using a permit-to-work system alone does not, in itself, make a work activity safe. It’s a formal written system that forms part of the risk assessment process and contributes to the safe system of work. It does not replace either of them.

Emergency Arrangements

Properly planning for emergency situations is essential for work activities involving confined spaces. Failing to do so, can have serious consequences. It is legally required that emergency arrangements are planned and enforced before entry or work in a confined space commences. Rescue arrangements must cover all six of the specified risks, as well as any others identified in the risk assessment that may require a worker to be rescued. Emergency arrangements must form part of the risk assessment process and safe systems of work.

For more information on emergency arrangements for confined space working, take a look at our Working in Confined Spaces Online Training Course.

Personal protective equipment (PPE)

PPE must only ever be used as a last resort. Where reasonably practicable, avoidance of risk, substitution for safer alternatives and engineering controls must always be in place, followed by the enforcement of safe systems of work, including a permit-to-work.

Examples of PPE that are regularly used in confined spaces include safety helmets, gloves, safety footwear, and anti-static clothing. Examples of more specific PPE that may also be used include safety lines, harnesses and, in exceptional cases, the use of breathing apparatus.

A significant majority of confined space incidents occur as a result of inadequate planning, controls and training. These incidents can be avoided by ensuring that the proper planning, controls and training are in place before confined space work commences. As previously mentioned, this article only briefly discusses the controls that may be used for confined space working. For more information, and training for those working in confined spaces, take a look at our Working in Confined Spaces Online Training Course.

Further Resources:

- Online Health and Safety Courses

- What are the Emergency & Rescue Procedures for Working in Confined Spaces?

- 3 Case Studies of Working in Confined Spaces

- Permit to Work Quiz

- What are the Requirements for Working in Confined Spaces?

- Establishing an Effective Lone Working Buddy System

- Working In Confined Spaces Training Course