Food Safety & Hygiene Level 2 Course for Catering

Quantity: 1

Duration 2-3 hours

Last audited 6th March 2025

100% online training

Start when you like

Learn on any device (desktop, mobile or tablet)

Instant assessment and result

1 learner per course

Train teams of all sizes

Bulk discounts starting at 10% off 10 courses

Pay by invoice with 30 day payment terms available (5+ courses)

Includes a 10% discount for 10+ courses

This Level 2 Food Hygiene and Safety course is for anyone who handles, prepares or serves food in the catering industry. By law, all food handlers must have an understanding of the principles of food hygiene and know how to work safely to protect the food they serve from contamination.

This Level 2 course informs you of your legal responsibilities and what constitutes best practice for controlling food safety hazards, controlling temperatures, food storage, food preparation, personal hygiene and premises cleaning. You learn through a range of interactive exercises, written text, and video content.

Upon completion of this training, you will be confident in your food hygiene knowledge and have all the skills and tools you need to keep people safe and comply with food hygiene law.

100% online training

Access anywhere

Same day digital certificate

Printed certificate posted next working day

Full audio voiceover

Assessment retakes at no extra cost

Meets UK and EU legal requirements for food handlers

Accepted by Local Authorities

Accredited by CPD, assured by RoSPA Qualifications and endorsed by the Institute of Hospitality

EHO approved training

Bulk discount for orders of 10+ courses

This level 2 course provides learners with knowledge to an industry recognised standard

Save on our courses when you buy more training upfront. Lock in a better price now and access the training whenever you need to. You can mix and match any of our courses too and get the discount off your whole order.

10+ courses = 10% off

50+ courses = 20% off

100+ courses = 30% off

500+ courses = 40% off

High Speed Training is proud to be working in partnership with Magic Breakfast to ensure that no child is too hungry to learn and thrive.

Magic Breakfast works with schools within high levels of disadvantage to offer students a free, nutritious breakfast and ensure they start their day the right way.

With every Level 2 Food Hygiene for Catering course we sell we’ll donate the cost of a breakfast to enable Magic Breakfast to provide food that is stigma free and open to all.

By the end of this food hygiene course, you will be able to:

Accredited by CPD

All of our courses are accredited by the CPD Certification Service as conforming to universally accepted Continuing Professional Development (CPD) guidelines.

Assured by RoSPA Qualifications

This course is also assured by the Royal Society for the Prevention of Accidents through their RoSPA Qualifications Assurance System, as providing up-to-date, quality and content-approved training.

Endorsed by the Institute of Hospitality

Additionally, this course is endorsed by the Institute of Hospitality as providing independently-evaluated, quality content that teaches good practice standards.

Audited and approved by EHOs

This course has been audited and approved by Environmental Health Officers: the training materials have been independently reviewed and are verified as containing the necessary knowledge to achieve the level of training specified.

Recommended renewal:

3 years

What does this mean? This certificate does not have an expiry date, however, based on industry best practice guidelines there is a recommended renewal period.

Looking for more information around food hygiene certificate renewal dates? View our guidance and explanation of food hygiene certificate renewals.

Our in-house Learning Designers develop all of our courses to give you and your learners the most engaging training possible.

Over 2 million cases of foodborne illness occur in the UK every year. The risk of illnesses from food increases when workers involved in the preparation, handling and serving of food do not have the information or training necessary to enable them to work safely and hygienically.

Food businesses have a legal responsibility to protect consumers from food that is damaging to health, from receiving food that is not of the nature, substance or quality which consumers expect and from food that is labelled, advertised and presented in a way that is false or misleading. Failure to comply with your duties and responsibilities as a food business may result in action being taken against you by the Food Standards Agency (FSA) or other enforcement agencies. Level 3 Food Hygiene in Catering training would be more appropriate for food business owners, managers and supervisory staff. This Level 2 course is more suitable for staff in non-senior roles.

Employees involved in the preparation, handling and serving of food can be at risk of causing foodborne illnesses if the risks are not managed effectively. Food businesses must provide employees with information, instruction and training suitable to the work that they are carrying out. This will ensure that they understand the food safety legislation and practices in place, helping to protect the health and safety of themselves and others. By taking our Food Safety & Hygiene Level 2 for Catering course, employees will learn about food hygiene and the law, helping them to recognise and work towards best practice principles. The course will explain responsibilities, how to prepare, handle, store and serve food safely, as well as how to maintain high standards of food hygiene.

This module outlines your responsibilities and the actions you must take to ensure you comply with food safety law. It explains what you can expect from your employer, HACCP and the purpose of food safety management systems and the role of enforcement officers.

This module covers the various microbial hazards you may encounter in food handling and how to prevent them. It also explains how to prevent cross-contamination and the differences between low-risk and high-risk foods.

This module details physical, chemical and allergenic hazards, the risks they pose to food safety and the ways in which you can prevent contamination from occurring.

This module explains the importance of storing foods at the correct temperatures. It covers deliveries, how to correctly store different types of food, best before and use-by dates, stock rotation systems and food labelling requirements.

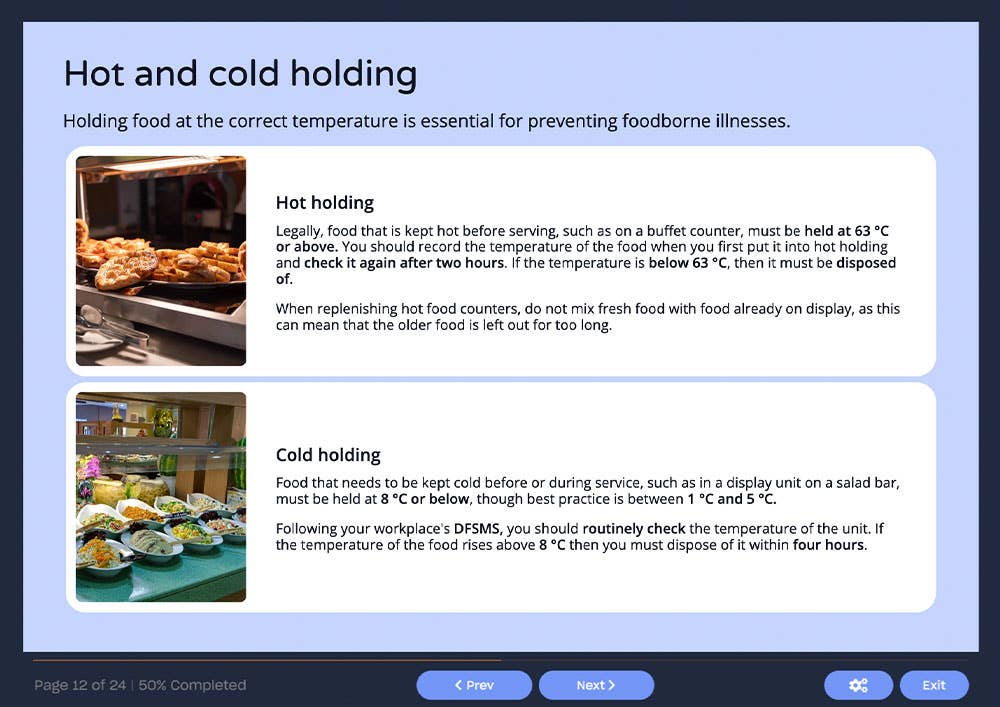

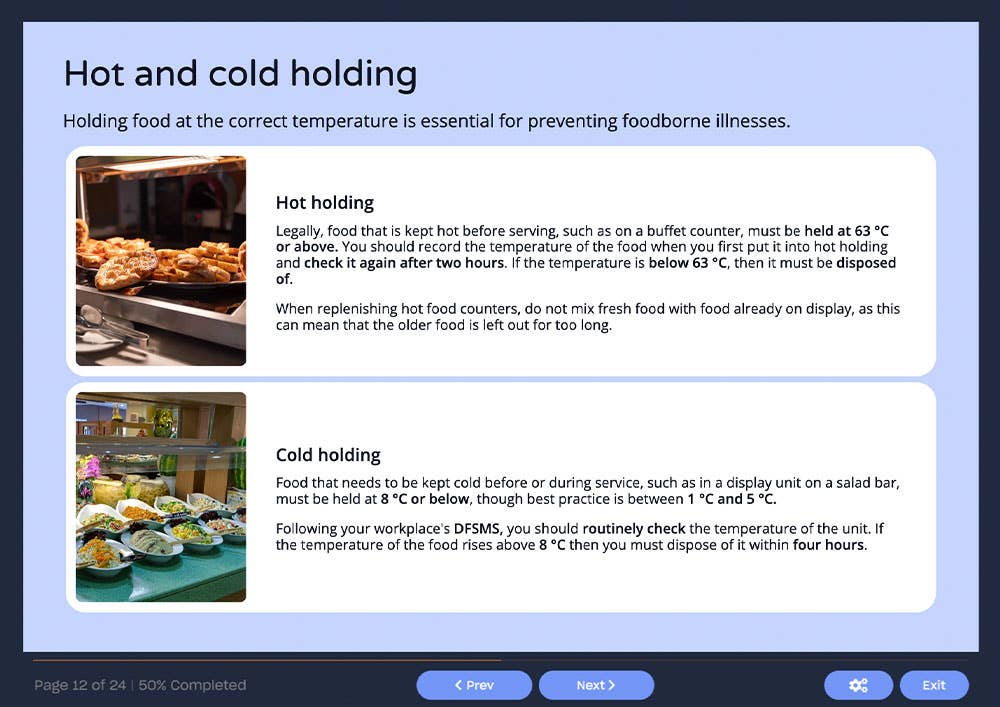

This module explains how to safely prepare food, including proper thawing, cooking and reheating methods. It also covers safe practices for hot and cold holding and managing hazards during food service.

This module highlights the importance of maintaining high personal hygiene standards. It includes the importance of effective hand washing procedures, protective clothing, reporting illness and managing wounds and sores.

This module highlights the importance of effective cleaning and disinfection. It explores how premises design can affect food safety, how to identify and control pests and the correct waste management procedures.

The online assessment is taken on completion of the training material.

You will be asked 30 multiple choice questions with a pass mark of 80%.

The answers are marked automatically so you will instantly know whether you have passed. If you don't pass don't worry - you can take the test as many times as you need with no extra charge.

The European Union Regulation (EC) No 852/2004 on the hygiene of foodstuffs requires all food handlers to be appropriately trained in how to carry out their roles safely.

This Level 2 Food Hygiene and Safety for Catering course ensures that you comply with this legal responsibility by providing learners with a thorough introduction to the correct food handling practices.

The course is suitable for food handlers in all disciplines of the catering sector, including restaurants, hotels, cafes, bars, fast-food outlets, takeaways, mobile food trucks, kitchens, hospitals, schools and colleges.

This certified online training is ideal for people working in positions such as, but not limited to:

If you are a manager or supervisor in any of the above sectors, then our Level 3 Food Hygiene & Safety In Catering Course is more suitable for you.

Unsure which Food Hygiene course is right for you?

In partnership with

Paul Turner

Senior Environmental Health Officer

Paul Turner is a Senior Environmental Health Officer at North Yorkshire Council with a great passion for the highest standards of food safety. As well as holding a degree in Environmental Health and a HND in Applied Science (Biology) Paul has completed the following: Certificate of Registration with Environmental Health Officers Registration Board, Assessment of Professional Competence (CPD), ISO 9000:2000 Lead Auditor qualification and has Chartered status from CIEH.

Paul has 30 years of experience in the sector working for local authorities and is on the Food Standards Agency’s (FSA) working group and is a Local Authority member of the FSA group contributing to their Register a Food Business (RAFB) service.

Paul is an experienced public speaker on food safety who has developed and delivered training on behalf of the Food Standards Agency and others in the sector as he continues his drive to ensure the highest standards of food safety.

My team like the interactivity and constant check of knowledge. This is great as a number of our staff have different learning styles.

Isha Hussain

Regional Manager at The Caramel Tart Company

No. Whilst this course does build on the foundation our Level 1 Food Hygiene Course gives learners there is no need to take that course before attempting this one. Level 1 Food Hygiene is designed for people working in hospitality who do not handle or prepare food.

Yes, this course will help you to comply with food hygiene law and satisfy your local authority as it's written in accordance with industry guidance set out by food hygiene legislation.

We recognise how important it is for businesses to apply good food hygiene practices. We work with independent Environmental Health Officers (EHOs) and Practitioners, who have years of experience inspecting, auditing and giving technical advice to food businesses, to ensure our Food Hygiene courses provide accurate and accessible information relating to food hygiene requirements. We also communicate with them for advice on any legislative changes, so we can always provide up-to-date compliance training.

Whilst we outline a few job roles in the 'Suitable for' section of this page, we've got a couple more resources to help you make absolutely sure which course is right for you. First is our Food Hygiene Course Selector that lets you enter your job role and provides the best recommendation for you. We also have our complete A-Z Food Hygiene Job Roles guide which goes through every job we could think of and explains the most appropriate level of food hygiene training and the industry for the course we'd recommend.

If you still aren't sure or have any other questions please contact our support team who are more than happy to help.

Yes. Anyone that handles or prepares food needs to take a Level 2 Food Hygiene course, or be able to demonstrate they have taken an equivalent level of training.

After completing your purchase, you should have received a confirmation email which was sent to the email address entered at the time of payment. If you haven’t received this, please check your junk/spam folder.

To access the courses, click the ‘Get Started’ button within this email and select the option which best reflects what you’d like to do with your training. You will then be able to add the course(s) into your existing account, or create a new account.

If you have purchased the course(s) for other people, please do not forward this email on to them as this will prevent some of your learners from accessing the courses.

Once you have purchased your course(s), you will receive an email containing your receipt, and a link to access the training. Simply click the "Get Started" button and select who the training is for.

If you purchase courses for your team, you'll get access to our Management Suite which is a tool that will allow you to allocate, track and review the training of your staff members. We also offer free training sessions on how to get the most from your Management Suite. To benefit from this, please contact: managersupport@highspeetraining.co.uk and we’ll happily book you in.

Yes, our bulk discounts are automatically applied to orders containing any combination of courses. We offer the following discounts on bulk purchases:

If you purchase 10+ courses you receive a 10% discount

If you purchase 50+ courses you receive a 20% discount

If you purchase 100+ courses you receive a 30% discount

If you purchase 500+ courses you receive a 40% discount

You can pay for our training using either a Debit or Credit card.

For companies ordering 5 or more courses, you’ll also be given the option to pay by invoice. If you would like to pay by invoice for fewer than 5 courses then please contact our Sales Team by calling 0333 006 7000 or emailing us at sales@highspeedtraining.co.uk.

Yes. You can use your username and password to log in and revisit the training material as many times as you like, even after completing the course.

No, we want our courses to work around you so there’s no time limit in which you must complete the training after making a purchase. You can also split your training over as many different sessions as you wish, as course progress is saved as you make your way through the training. You’re free to learn entirely at your own pace.

We work with the charity Magic Breakfast (Charity No. 1102510, Scottish Charity No. SC048202) to help provide healthy, nutritious breakfasts to school children in disadvantaged areas of the UK. For every Food Hygiene and Safety Level 2 Course for Catering course sold High Speed Training will donate £0.28 to Magic Breakfast to support their work and fund the equivalent of one breakfast for one child.