PPE in Construction: Safety Guidance and Checklist

Importance of PPE in Construction

The construction industry reports the highest number of fatal injury accidents every year. Even after thorough risk assessments and the implementation of adequate controls into a work environment, workers could still be subject to health and safety risks from hazards, which is why PPE is so important.

Personal Protective Equipment (PPE) includes all equipment (even those used to protect against adverse weather conditions) used to protect employees from health and safety risks they might encounter at work, including injuries to the lungs, head, eyes, ears and skin.

Where required, wearing task-appropriate, well-fitted PPE can be the difference between life and death in the event of an accident.

Types of Personal Protective Equipment

When selecting PPE, it is important to ensure that:

- The products chosen have the correct conformity marking. As a result of Brexit, Great Britain (England, Scotland and Wales) is in a transition period regarding conformity marking and conformity assessment of products manufactured or supplied for sale in Great Britain. All new PPE supplied in Great Britain must be marked with the appropriate conformity marking (UKCA, or CE prior to the deadline for UKCA implementation), or be accompanied by documentation that is marked with it. There are different requirements for Northern Ireland.

- The equipment is tailored; the correct size, fit and weight of the PPE must be chosen for every user, so it is safe and easy for them to make use of.

- If multiple items of PPE must be worn simultaneously, all the equipment can be utilised effectively together. For example, do not use safety glasses that disturb the seal of a respirator.

- Workers are properly trained and instructed on how to use their PPE. Ensure they are aware of the PPE’s limitations, why it is needed and when they should use it.

Need a Course?

Our PPE Course is designed to familiarise you with all the fundamental aspects of PPE that is used in work environments. With this knowledge, learners will be fully prepared to select and use PPE properly so health and safety is upheld at work.

Head Protection

Head protection is required on almost all construction sites. It is important for construction work to be organised to minimise all risks to workers, however, it is likely that hazards will still remain and everyone will be required to wear safety helmets at all times while on site.

To comply with the Personal Protective Equipment Regulations 1992, employers must provide all employees with, and ensure they wear, suitable head protection.

Employees should be provided with a safety helmet or hard hat for use at work; bump caps only protect from non-moving hazards and are not adequate protection for construction workers.

The only exception to the ‘hard hat rule’ is for Sikhs who wear turbans. They are exempt from the legal responsibility of wearing a hard hat on site, however, it is important to stress the risks they are taking by not wearing head protection.

Acceptable head protection should:

- Be in good condition. Do not wear damaged PPE. If it’s damaged, it must be thrown away and replaced by the employer.

- Be a good fit for each individual and be worn properly.

- Not prevent someone from wearing hearing protection when required.

- Only be purchased from a reputable supplier.

Ear Protection

Ear protection is needed to protect workers from noise hazards. Both the exposure duration and the sound level workers are submitted to can contribute to ear damage. Even if workers are only subjected for a short duration, very high-level sounds can still pose a hazard to the ears. Therefore, it is necessary for all workers to be provided with the correct type of hearing protection for the type of work they are undertaking.

The options available for ear protection are earplugs, earmuffs and semi-insert/canal caps. Ear PPE must provide a suitable level of protection for the work being undertaken and must not compromise safety or communication. All workers must also be clear on how to wear their PPE correctly, to ensure maximum protection.

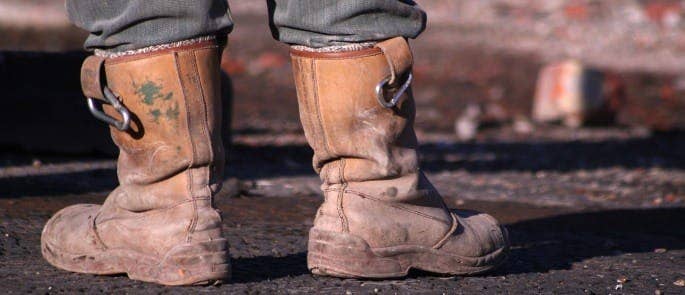

Foot and Leg Protection

Construction workers are always be expected to wear protective footwear while on site.

The bones in the foot are easily damaged, with an injury to muscle or tendons potentially prohibiting normal foot movement for several months. Therefore, it is highly important to take precautions that minimise the risk of a foot injury. The ideal foot PPE encompasses steel toecaps, to protect from dropped objects, and steel midsole protection, to protect against puncture or penetration wounds from stepping on sharp objects.

The employer must provide a basic standard of footwear (or a suitable kit for individuals who cannot wear basic footwear for medical reasons) free of charge, on the condition that employees look after their equipment appropriately and make it last for a reasonable length of time.

What About Rigger Boots?

Rigger boots have seen a surge in popularity over recent years, likely because they are a cross between lace up boots and wellingtons and are simple to put on. But, due to their loose fit, rigger boots leave workers more susceptible to sprained or twisted ankles as workers are unable to stop their foot from twisting when walking on uneven ground. For this reason, some contractors refuse to allow rigger boots on site. This is a justifiable argument against rigger boots and workers are expected to understand the reasoning and comply with the contractor’s ruling.

However, when working with asbestos or cement, rigger boots might be the preferred type of foot protection. This is because boots without lace holes provide a greater deal of protection in this case as cement and asbestos are prevented from entering the PPE.

Can Workers Wear Shorts?

Whether workers are allowed to wear shorts on a construction site depends on the site’s policy. Clothing worn on construction sites must protect against hazards. Wearing shorts could leave the lower leg vulnerable to various injuries that could become infected, as well as weather conditions and trade specific hazards (such as overexposure to UV light when working with arc welders).

If the site policy states that workers must not wear shorts to work, then everyone is expected to adhere to the ruling.

Eye and Face Protection

It is important to wear eye and face protection when at risk of hazards involving chemical or metal splashes, dust, projectiles, gas, vapours and radiation.

The types of eye protection available are:

- Saftey spectacles.

- Goggles.

- Face screens.

- Faceshields.

- Visors.

When selecting eye and face protection, it is important to ensure that it is task-suitable and that the correct fit is selected for each worker. If not, workers will still be vulnerable to risks.

Lung Protection

Lung protection is commonly required when working on a construction site as workers often encounter hazards such as dust, gases and vapours. When selecting lung PPE, it is important to ensure that the chosen piece of equipment fits the intended user properly. If incorrectly fitting respiratory PPE is selected, an adequate seal might not be formed, leaving workers susceptible to workplace hazards.

Examples of lung protection include:

- Filtering facepieces.

- Respirators.

- Power-assisted respirators.

- Self-contained breathing apparatus.

- Fresh-air hose.

It is important to ensure that the right type of respirator filter is used for the specified hazard, as each filter is only suitable for a small range of substances. Additionally, filters only have a limited lifespan. Therefore, if exposed to high levels of harmful fumes, confined spaces or atmospheres with a shortage of oxygen, workers must only use breathing apparatus, never use filtering cartridges.

Whole Body Protection

When working on a construction site, there might be occasions when workers are required to work with contaminated dust (such as asbestos) or may be at risk from chemical or metal splashes, spray from pressure leaks or spray guns, entanglement of their own clothing, impact or penetration. In these situations, the use of conventional or disposable overalls, boiler suits, aprons or chemical suits made from various materials, might be required to protect from workplace hazards.

Identifying Fake PPE

Fake PPE can kill. Safety helmets are currently the most common version of faked PPE on the market, with some fakes being weak enough that they can be snapped using only your bare hands. Fake safety helmets would definitely not provide a high standard of protection if a hazard was encountered. It is important for everyone’s safety to know how to detect fake PPE.

Some key hints that PPE might be a fake are:

- The PPE is not a uniform colour throughout.

- The markings on the PPE are not clear or legible, and the product is not durable.

- The user information leaflet provided is a photocopy, rather than an original.

- The information leaflet contains spelling errors and does not list the manufacturer’s contact details.

Helmets are not the only item of PPE that can be faked, and if workers have any concerns about the PPE they have been provided with, they should raise the issue with their employer. If workers are not content with the assurances that their employer provides, and still believe there are issues with the legitimacy of the PPE provided, they should contact their regional office.

What to Read Next:

- Personal Protective Equipment at Work: Health & Safety Guide

- Refusal to Wear PPE: Guidance for Employers

- Understanding the Classification of Grinding Wheels

- PPE Quiz

- Hard Hat Colour Codes in Construction: What Do They Mean?

- Ten Common Construction Site Hazards

- Toolbox Talks in Construction: Guidance on Meeting Topics and Resources

- What is Effective Communication in Construction?

- Protecting the Public During Construction Projects