Precautionary Allergen Labelling: Guidance on ‘May Contain’

Precautionary allergen labelling, commonly seen as ‘may contain’, is used on a number of food products to warn consumers that there may be a risk of allergens being present. While it is a crucial part of food labelling, it can be confusing to the consumer and difficult to understand what ‘may contain’ actually means.

In this article, we will define what ‘may contain’ means and when precautionary allergen labelling should be used. We will also discuss the requirements for ‘may contain’ labelling, and outline ways in which you can reduce the risk of allergenic cross contamination in your workplace.

What Does May Contain Mean?

It’s estimated that two million people in the UK are living with a diagnosed food allergy. For some people, consuming even trace amounts of an allergen is enough to cause an allergic reaction. In severe cases, this can be life threatening.

Precautionary allergen labelling, such as having ‘may contain’ included on the packaging, is used as a way of warning consumers that allergens may be present in a food, albeit unintentionally. It is a voluntary label added to a food product by manufacturers, and not a legal requirement.

However, by law, all food businesses must follow the allergen information guidance found in the EU Food for Consumers Regulation (EU FIC), written into The Food Information Regulations 2014. This means being able to provide accurate allergen information to consumers. It also involves understanding how to handle allergenic foods safely. The UK and EU requirement for food to only be placed on the market if it is not considered to be harmful to health must also be taken into consideration when labelling food products. More information about these regulations can be found here.

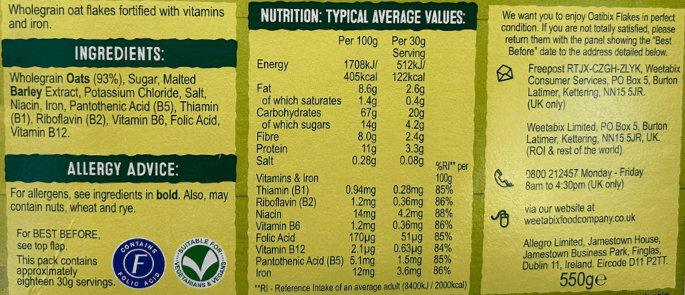

There are 14 named food allergens that legally must be declared if they are used as an ingredient in a food product.

Precautionary allergen labelling indicates that there is a risk of allergenic cross-contamination having occurred – where an allergen has contaminated the food product unintentionally during the food production process.

For example, allergenic cross-contamination can occur when several different food products are made in the same premises or if sufficient processes to keep allergenic ingredients separate aren’t implemented. We will look into ways in which you can reduce the risk of allergenic cross contamination later in this article.

Precautionary allergen labelling can be worded in several ways, for example, you could write:

- May contain peanuts.

- Not suitable for people with a sesame allergy.

Need a Course?

Our Food Allergens in Manufacturing and Food Allergens Awareness Training courses explain in detail the importance of labelling allergens correctly in order to prevent cross contamination and keep consumers safe from harm.

When Should Precautionary Allergen Labelling Be Used?

Precautionary allergen labelling should only be used when there is a reason to do so due to the ingredients, or it has been identified that there is a legitimate risk of allergenic cross-contamination within the supply chain that cannot be controlled or managed.

Conducting an allergen risk assessment is an effective way of determining the potential allergenic risks in your premises. Before you conduct a risk assessment, you can also complete a checklist. This allows you to answer simple yes or no questions on the current procedures you have in place, and determine whether there are risks that need analysis or systems that need improvement.

You can find our free, downloadable allergen checklist and allergen risk assessment templates, here.

Precautionary allergen labelling must be used with caution. Excessive use can limit the choices for consumers unnecessarily and deter people with allergies from buying products that are perfectly safe, if used incorrectly. This can also devalue the warning for consumers with a food allergy or intolerance, leading to them potentially taking risks with which foods they purchase or eat. For someone with a severe allergy, this could be fatal.

If there is a risk that the product may be contaminated by an allergen that has not been deliberately included in the product, then there can be a voluntary statement made on the food label such as ‘may contain peanuts‘ or ‘not suitable for people with a sesame allergy‘. It shouldn’t be labelled as ‘may contain allergens’, however, as this can be seen as misleading to the consumer.

Need a Course?

Our Food Labelling Regulations Training course is designed as an introduction to food labelling regulations so that businesses understand how to label their food products legally and correctly.

Precautionary Vegan Food Labelling

Precautionary allergen labelling can also be used in combination with vegan or vegetarian

labelling. Voluntary claims on packaging such as ‘suitable for vegans’ and ‘vegetarian’ are covered by Food Information for Consumers (Regulation EU No 1169/2011 written into The Food Information Regulations 2014) and may be perceived by consumers in the same way that allergen food safety advice is. This perception could potentially be fatal to someone with a severe allergy.

Vegan and plant-based food products should not be assumed to be free-from egg, milk, fish, mollusc and crustacean, or any other of the 14 named allergens, by consumers.

For more information, check out our article: Vegan Food Products: What are the Labelling Requirements?

How to Reduce Allergen Cross Contamination

Allergenic cross-contamination occurs when allergenic ingredients are inadvertently transferred from one food to another. The contact between these two foods means that their proteins mix and, as a result, each food then contains a small amount of the other food. This results in an allergen-free food becoming contaminated and therefore unsafe for a customer with that allergy to eat. Proteins are very small and cannot be seen by the human eye, just like bacteria. However, these proteins could be fatal for someone who is allergic to them.

As a food manufacturer, it’s essential that you work to avoid allergenic cross-contamination at all times, from delivery of the ingredients through to dispatch of the final food product.

Below, we’ll outline ways in which you can prevent, or at least reduce, the risk of allergenic cross-contamination.

HACCP

Having a food safety management system in place, such as HACCP (Hazard Analysis and Critical Control Points) is essential for preventing cross-contamination. It allows you to identify the potential hazards in your premises so that the risk of harm to the consumer can be reduced and controlled.

A HACCP system highlights the areas of risk where allergenic contamination is most likely and explains which control measures to follow.

For example, the hazard analysis may identify that allergenic cross-contamination is likely when dry ingredients, such as nuts, wheat flour and sesame seeds, are put into storage. A control measure may be to keep these allergenic ingredients in a separate storage room.

As part of your HACCP plan, your workplace should:

- Have a clear policy on allergen control that is actively enforced.

- Ensure all members of staff understand the allergen policy and are regularly reminded of their responsibilities.

- Ensure senior managers lead by example.

- Ensure it is updated whenever there is a change to the product, process or premises.

You can find out more in our article: What are the 7 Principles of HACCP?

Sourcing Ingredients from Trusted Suppliers

When putting together your list of ‘may contain’ allergens, all of the cross-contact allergens from each ingredient within your product should be labelled, along with any process or premises cross-contact allergens. Therefore, a high importance must be given to the cross-contact allergens declared from your ingredients if you wish to reduce the number of allergens your product may contain.

For example, pine nuts are sometimes processed in factories that also handle peanuts on the same line. By using an ingredient with a cross-contact allergen (in this case peanuts), the final product also ‘may contain’ peanuts. Therefore, sourcing pine nuts that are made in a factory without any other cross-contact allergens will reduce the number of allergens the product may contain.

When looking for suppliers for your products, look for certifications and proof of processes in place to ensure they comply with UK law. For example, buying food items online that do not list their ingredients or allergen information is not a trustworthy source.

To avoid over labelling ‘may contain’ allergens from ingredients, only cross-contact allergens from the ingredients (and the product and premises) need to be listed. For example, a bakery which makes a pine nut pastry with a peanut cross-contact from the pine nuts only needs to label ‘may contain peanuts’ for that product. Their cinnamon swirls which do not contain those pine nuts do not also need to declare the same precautionary labelling.

Food Deliveries

The control of allergenic contamination must begin as early as ingredients and prepacked food products arriving at your factory. The contents of each delivery must be checked against the original order specification. This ensures that the ingredients and products received match what is expected.

To further control the hazards at the point of delivery, you should:

- Retain the ingredients lists for all prepacked food products in a central place where all members of staff can find them. These can be simply cut out from the product packaging or written onto a document.

- Make a note of any substitutions or changes in ingredients. For example, if a prepacked food product has been made to a new recipe, if your usual oil has been swapped for another or if a different brand of product has been sent, this must be recorded.

- Ensure that all members of staff know about any substitutions or changes so that customers and the relevant documentation can be accurately informed.

Food Storage

To control allergenic cross-contamination during refrigerated, frozen and dry storage, it’s important to:

- Keep prepacked foods in their original packaging where possible so that vital allergen information isn’t discarded. Otherwise, clearly label each product with the allergens that they do or may contain.

- If the outer packaging is removed, clearly label each product with the allergens that they do or may contain.

- Ensure that packaging is intact or containers are properly sealed to prevent allergenic foods from spilling onto allergen-free foods.

- Where products are decanted into other boxes, jars or containers, ensure they are clearly labelled and sealed. Never top up one brand or variety with a different one.

- Store ingredients that contain allergens separate from other ingredients. Where possible, use dedicated storage areas for allergenic ingredients.

- Use dedicated scoops to decant each allergenic product and never use the same scoop for allergenic and allergen-free products.

Food preparation and service in hospitality

In the hospitality industry, there is also a high risk of allergenic cross-contamination during the preparation and service of food.

At the preparation stage, it’s important to:

- Always stick to the planned recipes and only use the ingredients stated on the recipe information cards.

- Be aware of ‘hidden allergens’ in ingredients such as cooking oils, salad dressings, sauces and garnishes.

- Write down any changes to a recipe, or if an ingredient is substituted – even if it’s just the oil the meal is cooked in – and ensure all members of staff are informed of the change.

- Start afresh with clean utensils, knives, chopping boards, etc, when preparing an allergen-free meal. Never use the same utensils for everything or assume that a quick rinse under the tap will remove all traces of allergens. If the same utensils need to be used, then they must be washed thoroughly before handling allergen-free foods.

- If possible, make your least allergenic products first. For example, a bakery can make their gluten-free products first before their gluten containing products to further reduce the risk of cross-contamination.

If cross-contamination can’t be avoided, the customer must be told that an allergen-free product cannot be guaranteed.

In addition to the 14 named food allergens, any food has the potential to trigger an allergic reaction, which is why it’s so important to know exactly which ingredients make up the food products that you sell or serve. If a customer asks whether a dish or food product contains a certain ingredient, then all staff must be able to answer them accurately and knowledgeably.

In manufacturing, separate product lines or areas of the factory can reduce the risk of allergenic cross-contamination and ‘may contain’ allergens.

Personal hygiene

Maintaining high standards of personal hygiene throughout the factory is essential in preventing allergenic cross-contamination. For example, it’s important that everyone washes their hands thoroughly after handling equipment used for allergenic ingredients, or after handling the allergenic ingredients themselves.

In order to wash your hands effectively:

- The water temperature needs to be between 35°C and 45°C. This is the equivalent temperature of a hot bath.

- If possible, use a sink with a non-hand-operated tap.

- Wet your hands and apply liquid soap, ideally from a non-hand-operated dispenser.

- Thoroughly wash your palms, backs of hands, wrists, fingertips and in between your fingers and thumbs.

- Rinse the soap off in clean running water.

- Dry your hands with a clean disposable towel. Reusable towels should be avoided as they can harbour bacteria.

To learn more, check out our article: The 7 Steps of Handwashing where you can also find a free, downloadable poster.

When working in an area with allergenic ingredients, wear colour-coded protective clothing to inform other people of where you work. This clothing should be changed if you move to another line, in which case clean clothing must be put on.

Signs reminding workers to wash their hands after handling allergenic products should be displayed around the factory, including in manufacturing areas, staff rooms and bathrooms.

All members of staff should be aware of the risk of cross-contamination between different areas of the factory. For example, workers on a plant that uses sesame seeds and egg should ensure these ingredients never reach another plant. Allergenic ingredients should never be present in production areas where they are not used.

Many factories ban all nuts from the site, including the staff room and canteen. You can ensure that this is upheld by communicating regularly with your staff, having an allergen policy and displaying a poster to remind them of the importance of following it.

Cleaning the factory

Thorough and effective cleaning plays an important role in reducing the risk of allergenic contamination.

To control the risks of cross-contamination, remember to:

- Follow a cleaning schedule and keep a record of cleaning activities.

- Use designated, colour-coded cleaning equipment to clean areas where allergenic and allergen-free foods are manufactured.

- Regularly launder your protective clothing.

- Carefully clean up any spillages of allergenic ingredients as soon as they occur. Use single-use cloths, not reusable ones.

- Ensure that complex equipment, such as mixers and weighing scales, is cleaned thoroughly before using it for an allergen-free product. Dismantle it carefully to ensure all parts get cleaned and no allergenic residue, such as powders and seeds, is left in hard to reach places.

- Never use the same equipment for allergenic and allergen-free foods without performing a thorough clean down in between uses.

- Be aware of other routes of cross-contamination, such as footpaths and routes in for raw materials, and ensure these are cleaned first.

Cleaning in place (CIP) is an automated method of cleaning. CIP removes residue from manufacturing equipment and pipelines without dismantling or opening the equipment. For example, thoroughly cleaning a beer tap before switching to cider to avoid gluten cross-contamination.

In manufacturing, if the CIP procedure aims to mitigate allergen cross contact, then this process must be validated and documented to ensure there are no allergens present after cleaning.

We hope you’ve found this article on precautionary allergen labelling informative and helpful. If you have any further questions, or wish to find out more information on the topics covered in this article, please don’t hesitate to get in touch with us at High Speed Training!

Further Resources

- Food Allergen Awareness Training

- Food Allergens In Manufacturing

- How to Create an Ingredients List

- Food Allergen Risk Assessment & Checklist: Free Templates

- Vegan Risk Assessment & Checklist for Food Manufacturers: Free Templates

- Food Allergen Labels: Free Download & Advice

- How to Identify Which Foods Contain Gluten