Food Packaging Materials: Regulations & Different Types

Changing the selling format of a product or starting a food business has many considerations – the focus being on allergen labelling, logistics and marketing – however it is also important to ensure the packaging is food safe. This article will outline food packaging regulations, how to identify the food safe logo and explain the different types of contact materials.

This article covers the following:

- What are Food Contact Materials?

- How Do I Comply With Food Safe Packaging Regulations?

- What Does the Food Safe Logo Mean?

- Will the Food Packaging Regulations Change After Brexit?

- Considerations when Choosing Food Safe Packaging

- Types of Packaging Materials for Food

Use the links above if you’d like to jump to a certain section of the article.

What are Food Contact Materials?

Food contact materials are materials that are intended to be, already in contact with, or can reasonably be expected to be, brought into contact with food. These can be obvious, such as a glass jar, or less obvious like a kettle, water pipes, beer taps, food mixing machinery or a coffee machine.

Restaurants and hospitality food premises looking to provide meal and drink kits, takeaway delivery and sell online now must consider the packaging types and materials for food that would previously have been served on a plate and in glasses.

A food safe contact material meets the criteria of Good Manufacturing Practices (GMP) legislation. In order to keep food safe, there are restrictions on the type of packaging that can be used ‘for food contact’. If a food contact material is not tested for food safety or does not meet the requirements, then there may be a risk to consumer health through the migration of harmful chemicals. Migrating chemicals from packaging could also change the taste and smell of the food product.

The risk to food safety from food packaging and choosing approved suppliers must be considered when putting together a Hazard Analysis Critical Control Point (HACCP) plan.

Need a Course?

High Speed Training provide online Level 2 & Level 3 HACCP Training to help you put together your HACCP plan.

How Do I Comply With Food Safe Packaging Regulations?

Food safe packaging and contact materials must be used by all food businesses to comply with the Food Safety Act 1990, which requires all food businesses to not ‘treat food in any way which means it would be damaging to the health of people eating it’.

The GB legislation ‘The Materials and Articles in Contact with Food Regulations 2012’ implements a number of EU regulations. Framework Regulations EC 1935/2004 specifically requires that food contact materials must not release their constituents into food at levels harmful to human health or change food composition, taste and smell in an unacceptable way.

- Ceramics – ceramics have limits for the amount of lead and cadmium allowed to migrate into food. To reduce the risk of sourcing ceramics which exceed these limits, you should source your ceramics from inside the EU and UK as suppliers are more likely to comply with the Framework Regulations.

- Water pipes – lead in water pipes and soldering has been banned in the UK for more than 25 years, however, it must be a consideration, especially if your house was built before 1970 and you are producing food from home. (For more information on how to sell your food to the public, read our article on ‘How to Start a Food Business From Your Home’)

- Brass fittings – brass is an alloy that can have lead added during manufacturing. When sourcing brass fittings, it is important you clarify to your supplier that you intend to use them in a food or drink application.

Want to learn more about food packaging? We offer a range of online training courses and, whilst our Level 2 Food Hygiene and Safety for Catering course will cover your hygiene requirements, our Starting a Home Food Business course goes into depth on the importance of safe food handling practices in your kitchen. Helping you learn how to write your business plan and how to get your products to your customers.

What Does the Food Safe Logo Mean?

The Framework Regulation (EC) No 1935/2004 requires food contact materials to either be marked with the words “for food contact” or the food safe logo, unless it is obvious that the contact material is for food contact.

The food safe logo is recognised and used internationally to indicate that the material is considered safe for food contact. Food safety assurance is given to packaging materials which are free of any toxic contaminants and will not potentially become a source of toxic contamination through use. You may see this logo on food and water containers, packaging materials and cutlery. The symbol is more important on materials that are ambiguous as to whether the container could be used to hold food.

The food safe logo does not ensure food safety under all conditions, as the food safe logo only covers food safety from carcinogens. For example, some packaging materials should not be used to hold hot food. It is important to check the packaging specification for the intended use of the material and have good communication with your supplier about how you intend to use their product.

Larger manufacturers who comply with additional GFSI (Global Food Safety Initiative) standards, such as BRCGS or IFS, will have additional requirements for the safety verification of the materials.

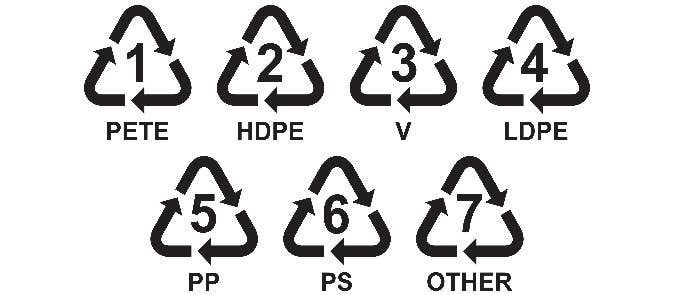

Plastic Resin IDs indicate the composition and recyclability of the plastic and do not communicate the food safe properties of the material. Therefore, the food safe logo is also needed.

Do Food Contact Materials Approved by the FDA (US Food and Drug Administration) Meet GB and EC Regulations?

FDA approval does not necessarily mean a material complies with GB and EU legislation. Additional checks will be needed to ensure the packaging meets GB and EU law.

Machinery and Food Contact Material Regulations

When considering materials and the design of machinery, the requirements of The Machine Directive EC 2006/42 must be considered. The Machine Directive states that ‘machinery must be designed and constructed in such a way as to avoid any risk of infection, sickness or contagion’. The surfaces must be ‘smooth and have neither ridges nor crevices which could harbour organic materials’.

The ‘Metals and alloys used in food contact materials and articles’ guide provides further guidance on the limits for harmful substance migration.

Will the Food Packaging Regulations Change After Brexit?

The food safe logo will not need a GB specific update as it is an internationally recognised and used symbol. The Framework Regulation EC 1935/2004 requires a food safe marking to meet the traceability requirements which are specified within the The Materials and Articles in Contact with Food Regulations.

The proposed amendments to The Materials and Articles in Contact with Food Regulations have retained the EU regulations. Non-compliance with the EU regulations mentioned within it will result in a penalty. The amendments to this regulation will apply to countries within Great Britain as Northern Ireland will still have to follow EU rules after Brexit. In summary, there are no major effective changes after Brexit to the laws and practices for food contact materials and food grade packaging.

Considerations when Choosing Food Safe Packaging

When choosing a food grade packaging material it is important to consider the intended use of the product and how your customer may use the product. Consider:

- What food safe material will the packaging be made out of?

- What is the type of food that will be packaged? Will it corrode the packaging?

- Is the packaging still food safe if hot food is placed in it or is heated in the packaging?

- Will the shelf life of the product be impacted by your packaging choice?

- What environmental conditions will the food and packaging be subjected to?

- How will the packaging be disposed of?

- How much will the packaging and distribution cost?

- Will the packaging be stackable and withstand the weight of stacking?

- Does the packaging provide a barrier which will protect the food from contamination and spoilage?

Types of Packaging Materials for Food

Glass – Glass is a good material for long shelf life foods as it is moisture and heat resistant. This allows you to heat treat the product after filling and it will not let air in providing the seal remains intact. Glass will not react with the food and can be made transparent to view the food inside the packaging. Glass can also be coloured, for example, a brown beer bottle to prevent light from affecting the product quality.

Glass is widely recycled and is perceived as a sustainable material. However, glass packaging will break if dropped or damaged and it is bulky and heavy to transport.

Metal – Metal packaging is usually made from stainless steel, aluminium and tinplate. The properties of food safe metal makes the packaging heat resistant, durable and the material is often widely recycled. Metal cans containing acidic foods may result in corrosion causing changes to the quality of the food, loss of barrier integrity and in turn its shelf life.

Paper and Cardboard – Paper and card packaging are lightweight and low cost in comparison to metal and glass. It is also a widely recyclable and compostable material. However, the barrier integrity of paper based packaging is compromised when in contact with moisture and humidity, making it easier to tear or damage.

Food Grade Plastic – Food grade plastic packaging is one of the best materials for the food safety and quality of a product. Plastic has good barrier qualities, meaning it protects the food once wrapped from potential contaminants. The barrier qualities of packaging will also impact the shelf life of a product and prevent it from spoilage or reducing in quality which, in turn, reduces food waste going to landfill. Some food grade plastics are also recyclable.

Polyethylene Terephthalate (1)

High-Density Polyethylene (2)

Polyvinyl Chloride or PVC (3)

Low-Density Polyethylene (4)

Polypropylene (5)

Polystyrene (6)

Other (7)

Compostable Food Packaging

However, compostable packaging will not have the same barrier properties as a plastic tray if, for example, a vacuum seal is required for freshness. Also, some compostable materials can only be composted through industrial processes which are not widely available.

Biodegradable Food Packaging

Biodegradable food packaging means that the food packaging will break down quicker. Often, biodegradable plastics break down into microplastics (smaller fragments of plastic). Biodegradable materials are a popular ‘greener’ alternative to plastic, however, microplastics are thought to be highly damaging if they end up in the ocean.

Plastics in food packaging have received a lot of media attention about their environmental impacts. When evaluating the environmental impact of your chosen packaging type, it is important to consider the energy it takes to manufacture the material. Paper packaging can use more than four times the energy to produce than its plastic equivalent, not including the additional energy used for the distribution of a heavier product.

Overall, when removing plastic or choosing a non-plastic packaging material the bigger picture of the environmental impact should be considered as well as the barrier qualities. Food packaging must not be harmful to human health or affect the taste and smell of the product to comply with GB and EU law.

A food safe logo does not necessarily guarantee food safety in every context and you must also consider how the packaging will be used by the customer. Ask the packaging supplier to provide evidence that the materials comply with the relevant requirements.

Further Resources:

- HACCP Training Courses

- What is Prepacked for Direct Sale Food? Free Infographic

- Allergen Regulations for Takeaways and Distance Sellers

- How to Start a Food Business From Your Home

- How to Sell Food at a Market: Safety Guidance

- What Does the BRCGS Grading System Mean?

- Understanding Factors Affecting the Shelf Life of Food Products

- What are the Different Types of Sustainable Food Packaging?

- How to Package Food for Shipping

- HACCP Quiz

- How to Transport Food